Building Structure Monitoring

IoT enabled continuous monitoring of building parameters help to predict and prevent structural risks.

Gain data insights about: mold risk detection, internal/external air pressure differential or concrete curing process.

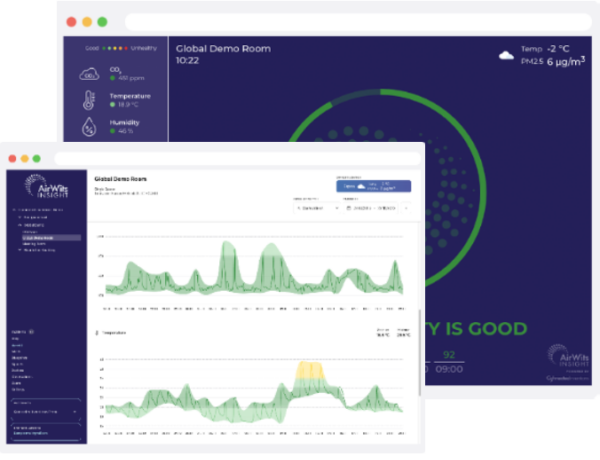

- Wireless, battery-powered IoT Sensors & Devices

- Simple IoT Management Platform & Dashboard

- Secure, energy efficient IoT connectivity services

Right data, at the right time without lifting a finger.

- Monitor what matters and gain real-time visibility and alerts without time consuming, costly manual checks.

- Continuous remote IoT-enabled monitoring of building conditions prevents damage, reduces structural risks, enables energy efficiency and protects the value of your commercial property.

- From construction phase to every-day operations, IoT insights help to increase structural resilience and longevity and enables streamlined, pro-active maintenance management.

IoT devices and sensors, connected to the internet, continuously monitor vital building parameters to help protect structural integrity and ensure long-term durability of structures. The data types include temperature, humidity, pollutants, CO2 and much more.

Without this automated data collection it is far more challenging to detect and prevent risks through proactive measures before costly damage occurs.

Connected Inventions’ IoT device, platform and wireless connectivity portfolio is optimised for Building and Facility Management and designed to integrate easily into your existing infrastructure.

Benefits of IoT data enabled Building Structure Monitoring

Easy access to real-time data insights and alerts without any manual effort.

Proactive Risk Mitigation: real-time monitoring of environmental factors can predict, or alert to, potential risks allowing pre-emptive actions to mitigate the risk.

Automated Data Collection: IoT enabled monitoring running for years maintenance free eliminates the need for regular manual process.

Cost Savings and Efficiency: Addressing potential issues before they escalate costly repairs, downtime and disruptions to operations can be minimised.

Early risk detection

Minimised Remedial Cost

Operational Efficiency

Damage prevention

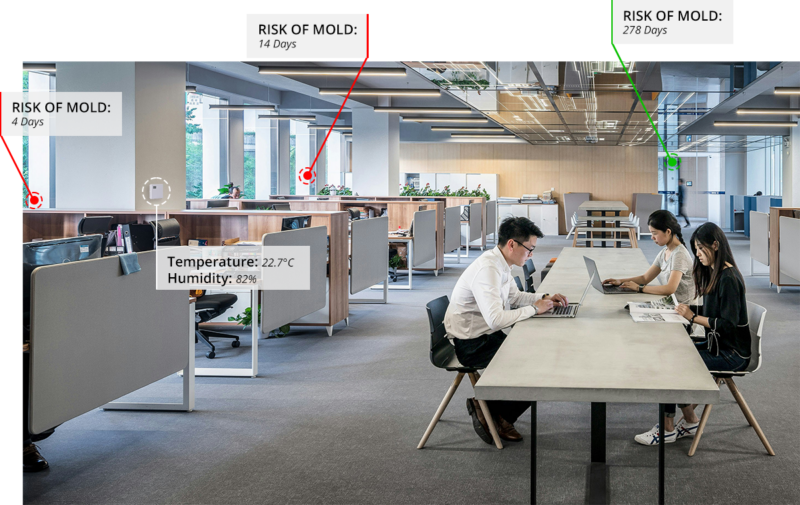

Mold Risk Detection – Predictive Monitoring

An innovative solution to proactively detect Mold Risk in indoor areas.

Our approach utilises a sophisticated formula applied to continuous temperature and humidity data collected by our IoT devices. The result is a precise risk indicator that assesses the probability of mold occurrence.

The solution offers:

Detailed Risk Scale: A detailed scale of risk factors for mold occurrence allowing you to take targeted preventive measures.

Predictive Analysis: Anticipate and plan ahead with the predictive capability that forecast the number of days it would take for mold to emerge based on current conditions

Customised Alerts: Stay informed and notified with Alerts tailored to your preferences ensuring timely actions when parameters are triggered.

You don’t have to wait for mold to become a problem. Benefit from proactive detection and prevention with Connected Inventions’ Mild Risk feature embedded into our IAQ solution.

Air Pressure Differential Monitoring to

Improve Building Performance

Balanced pressure differentials contribute to energy conservation by reducing the need for excessive ventilation or conditioning. HVAC systems can operate more efficiently, resulting in lower energy.

Monitoring pressure differentials provides insights into the overall performance of a building’s envelope, including its doors, windows, and ventilation systems.

Optimising Concrete Curing Process

Remote monitoring of temperature and humidity parameters can accelerate the construction processes by optimising the concrete curing time by weeks and ensure optimal conditions for strength and durability.

IoT data insights allow timely adjustment of conditions as needed, and can accelerate construction timelines, reduce material waste, and enhance the quality of concrete structures, leading to cost savings and shorter project times.

Case Study: Discover what you can achieve

See how our secure, cost- and energy efficient IoT data services empower building & facilities management to optimise indoor air conditions for a healthy, productive and comfortable space to work and learn.

Proven IoT Device & Sensor optimised for Facilities Management

Certified and proven to meet Green Building Standards

WELL

LEED

RESET

BREEAM

Connected Inventions | Customers & Partners